RECTANGULAR STAINLESS STEEL SLOT DRAINAGE

Recommended selection stages

Stage 1

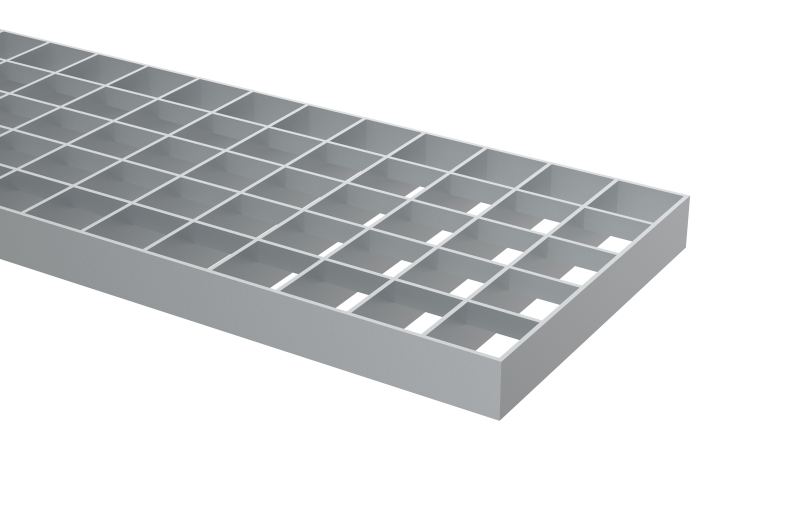

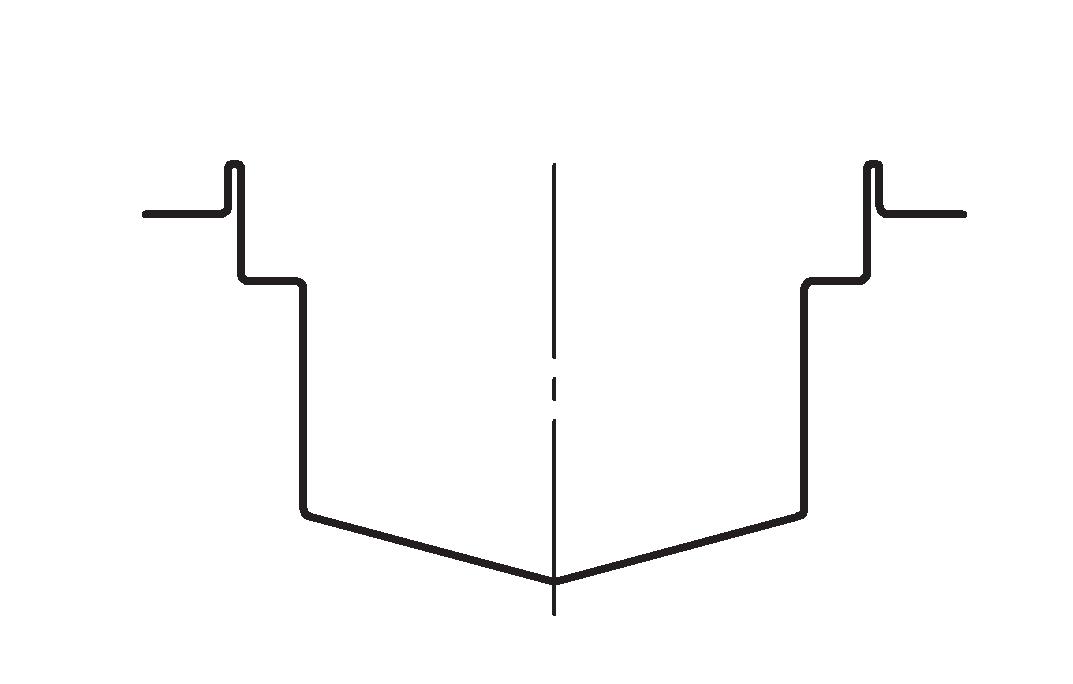

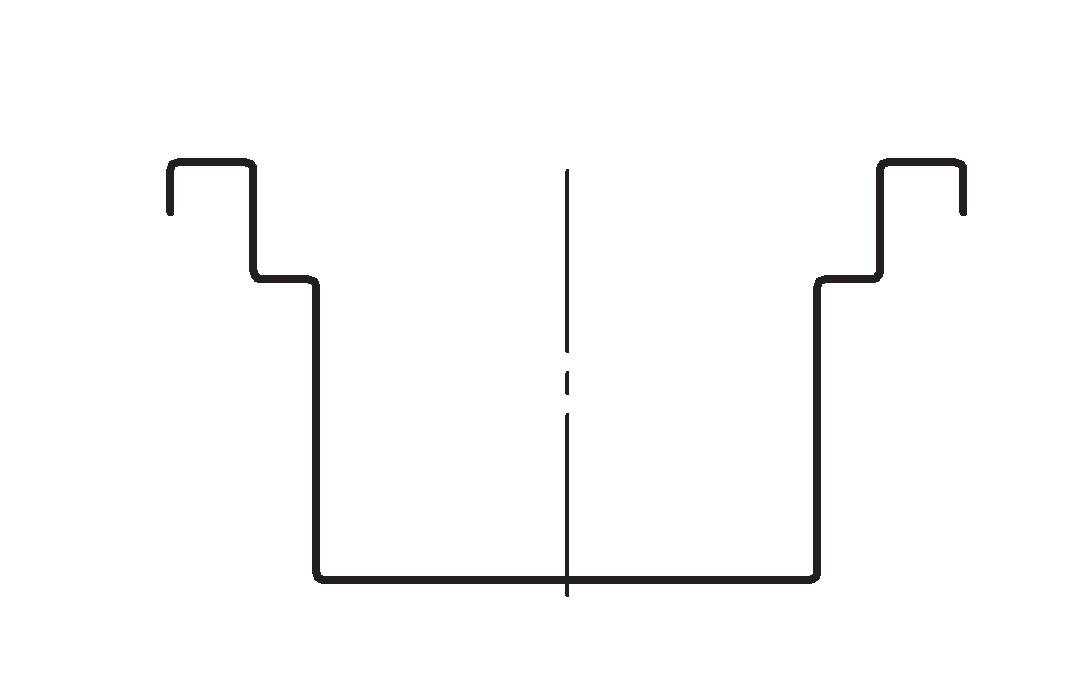

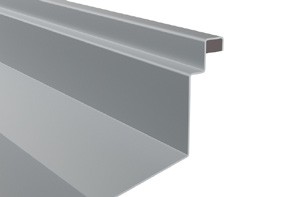

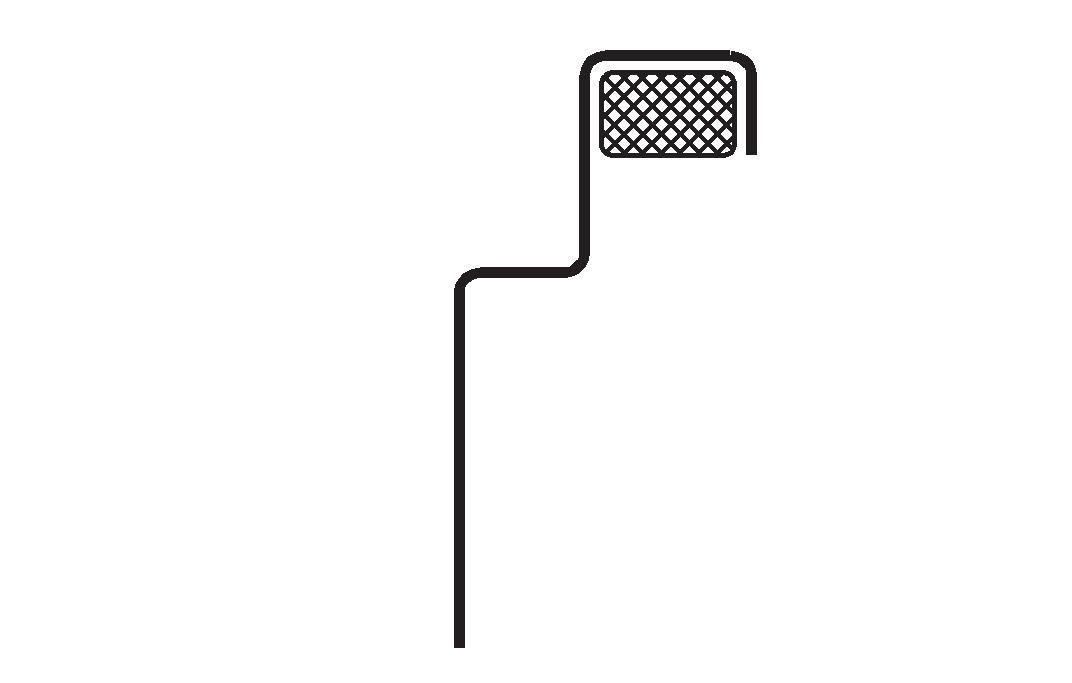

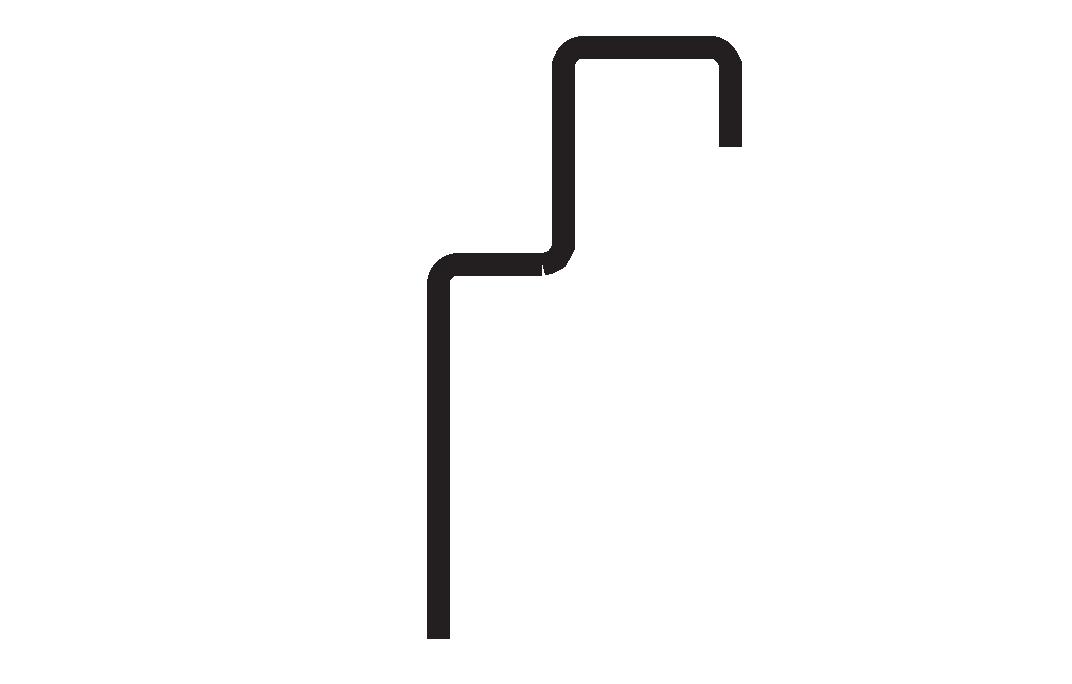

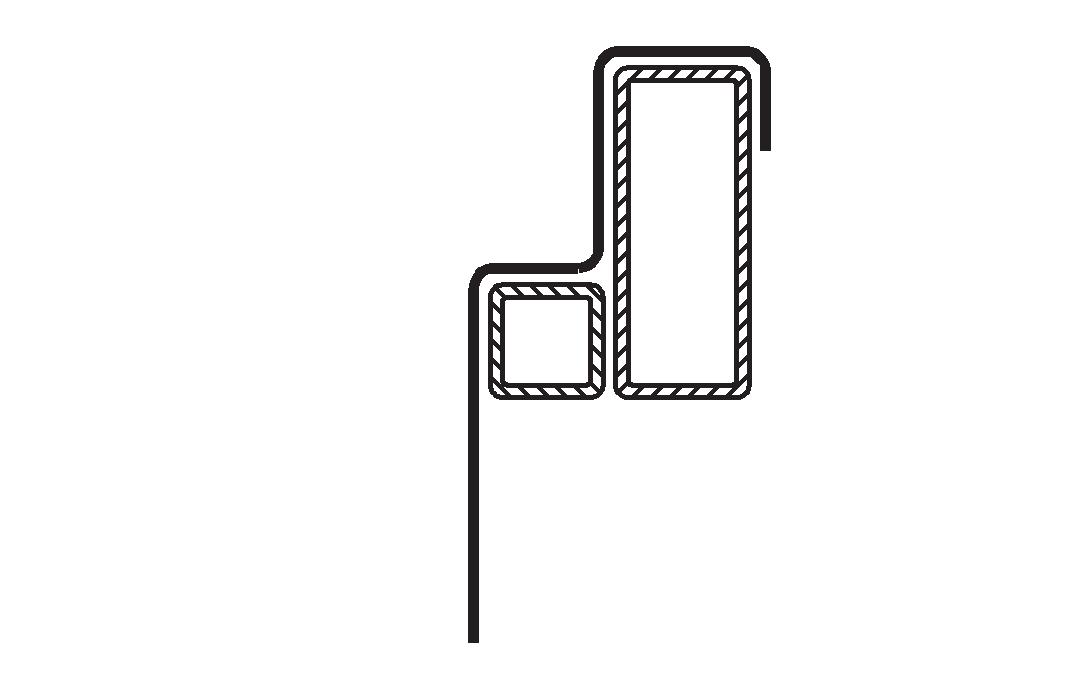

| RECTANGULAR SLOT PROFILES | ||

| Image | Scheme | Name |

|

|

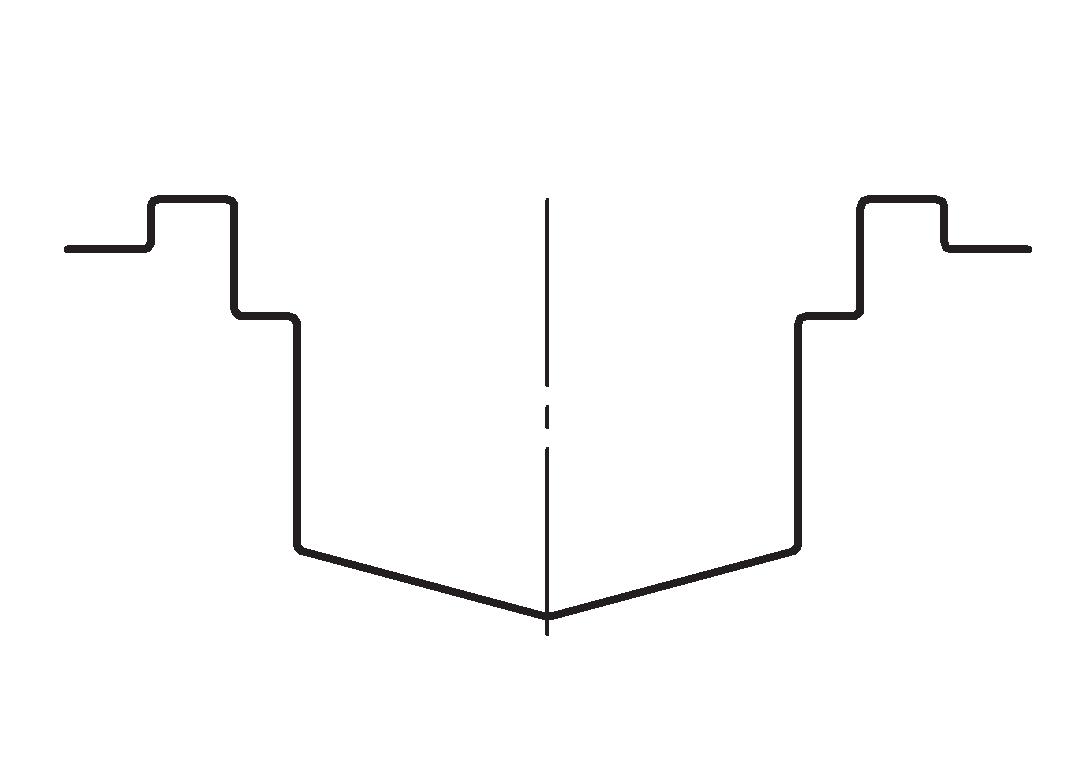

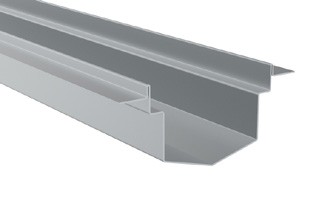

Rectangular cross section slot (standard) |

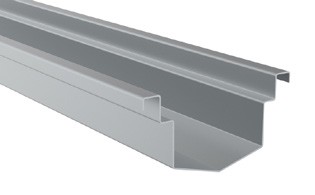

|

|

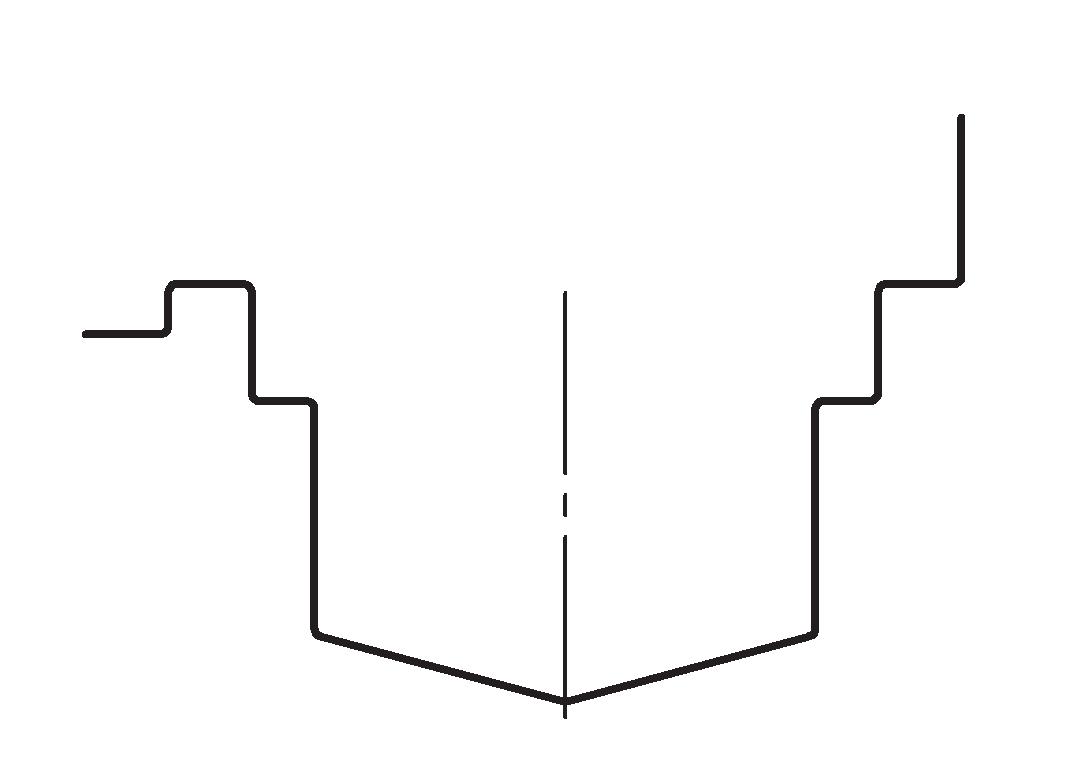

Rectangular flange slot |

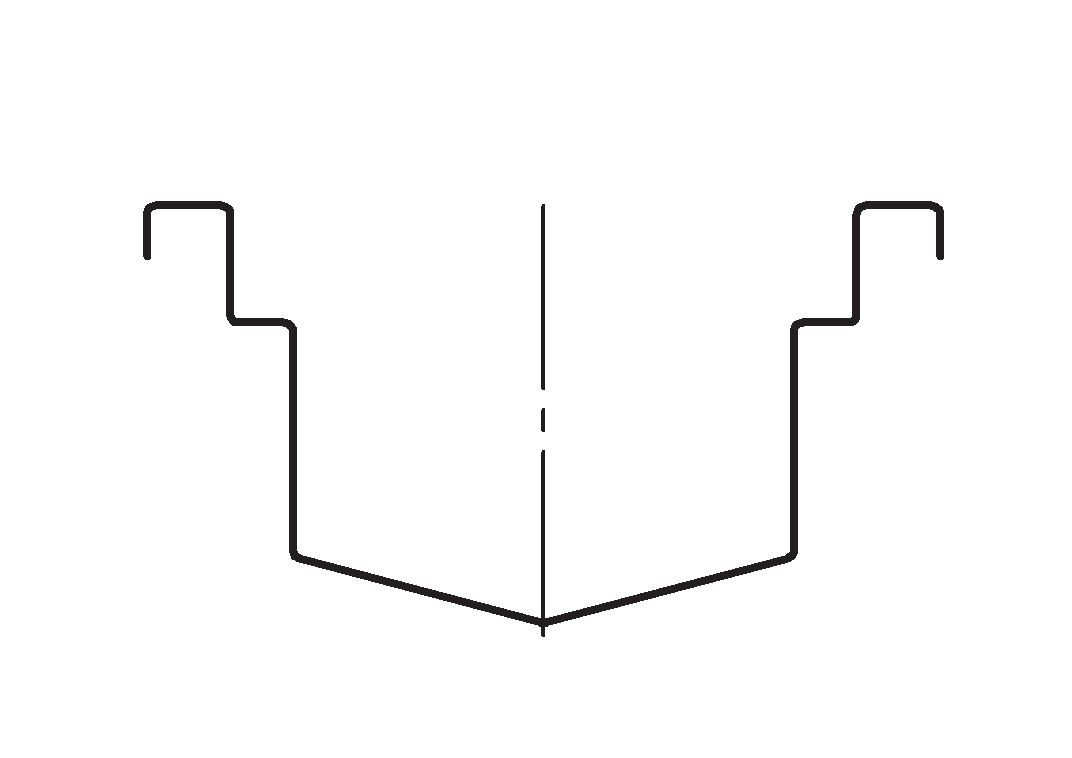

|

|

Wall slot |

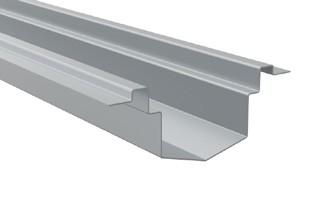

|

|

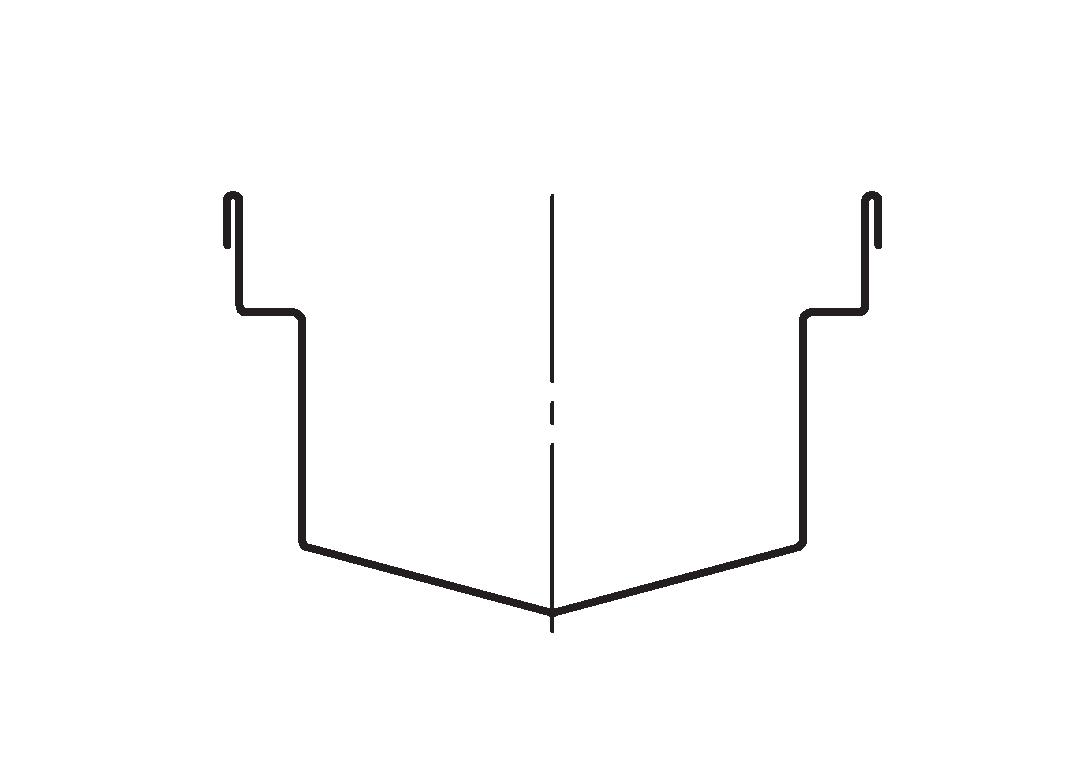

Folded flange slot |

|

|

Folded flange and membrane slot |

|

|

Flat-bottomed slot |

Stage 2

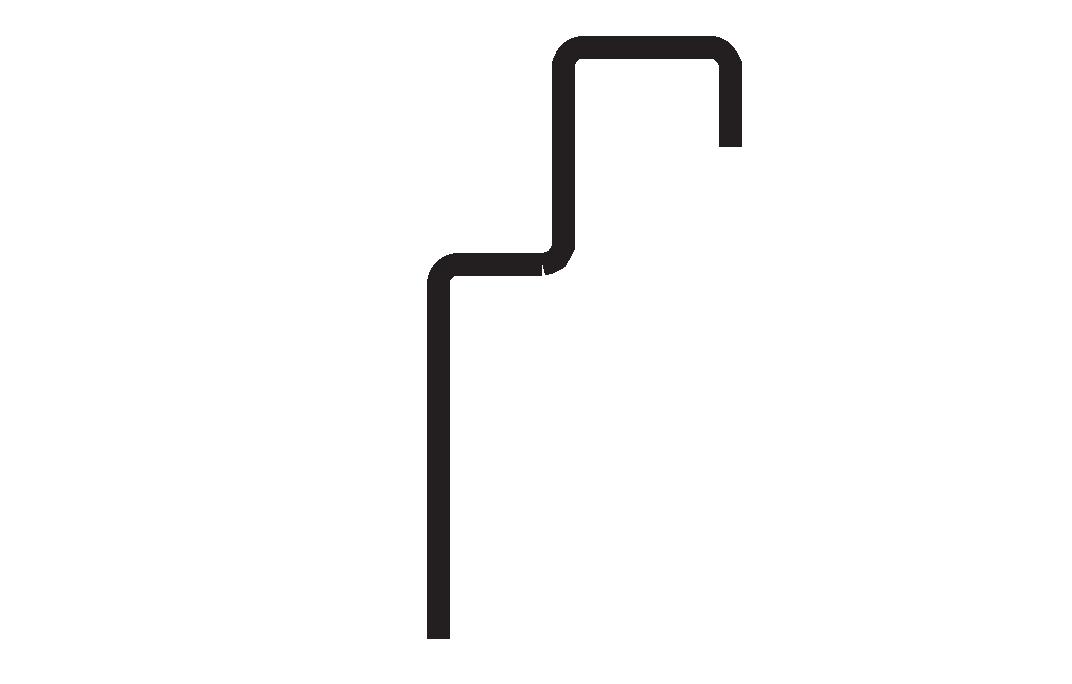

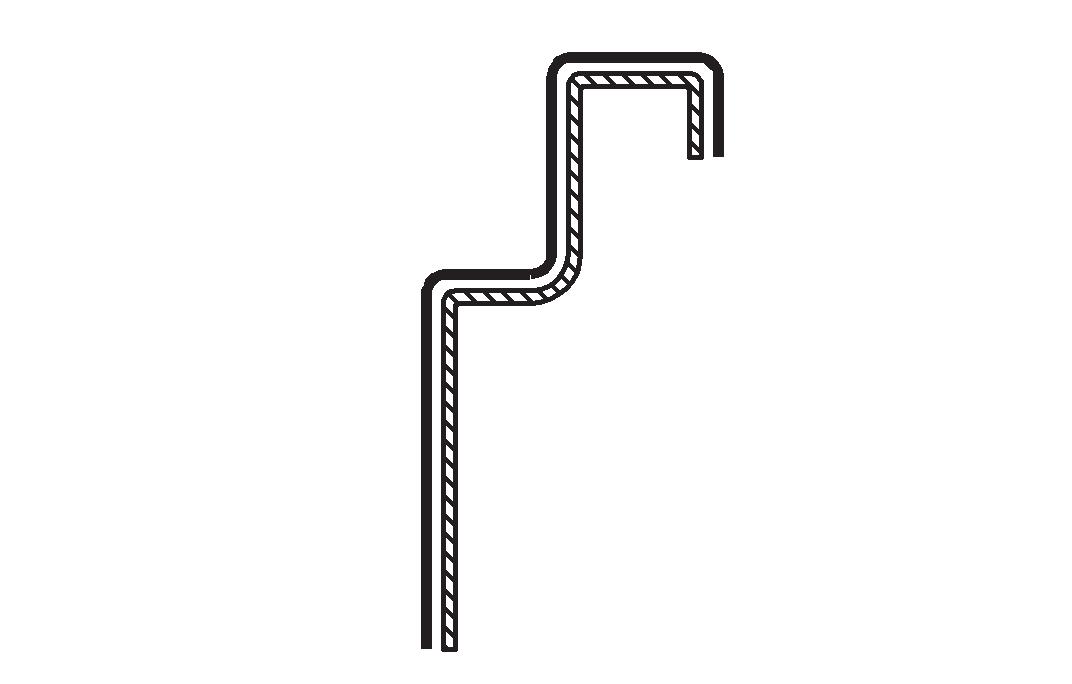

| Flange reinforcement | ||

| Image | Scheme | Name |

|

|

Metal density reinforced flange |

|

|

Additional profile reinforced flange |

|

|

Polymer reinforced flange |

|

|

Rolled steel reinforced flange |

|

|

Tube reinforced flange |

Stage 3

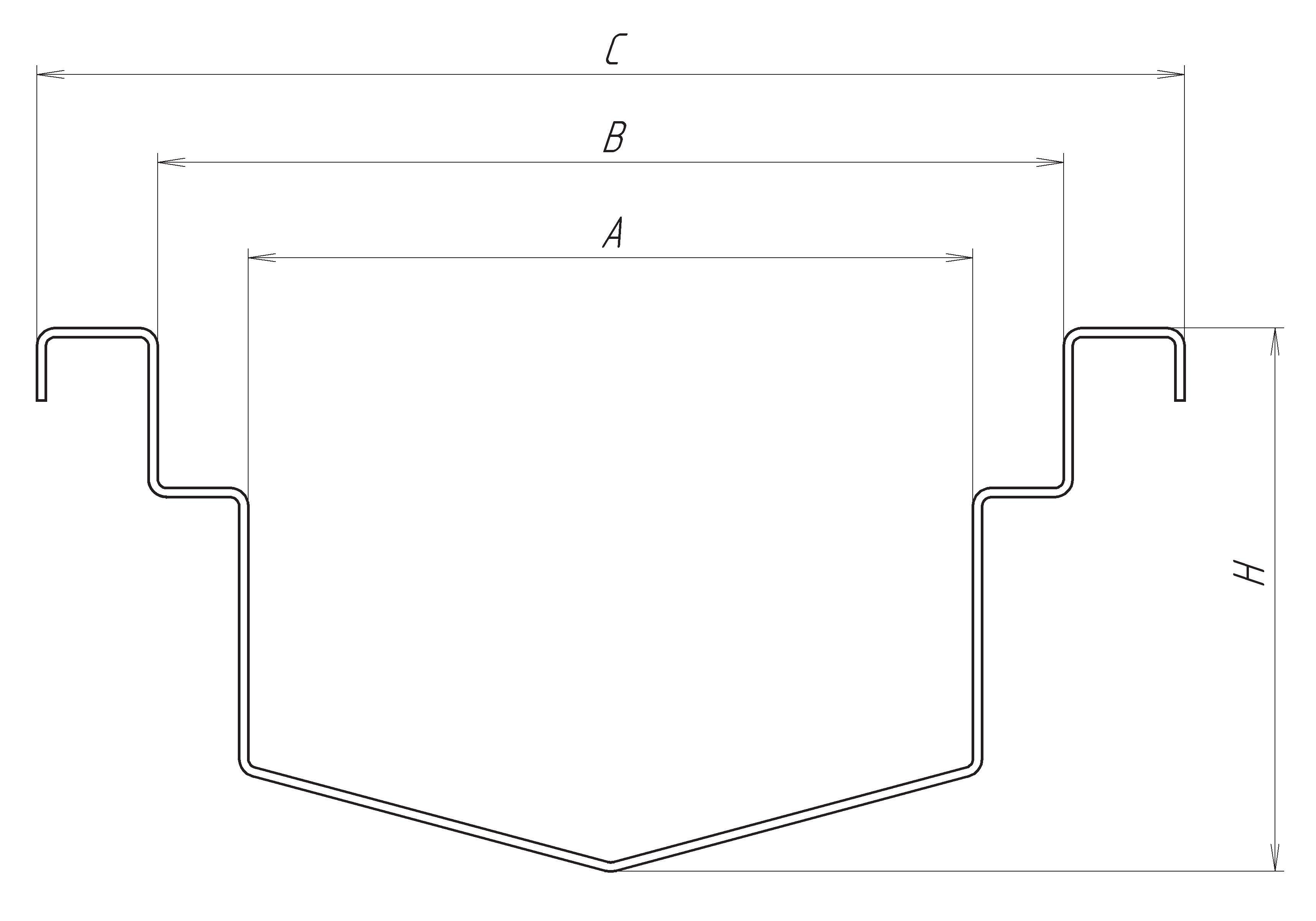

А – Working width

В - Build-in width

С - Overall width

Н - Slot height

| RECTANGULAR SLOTS SIZE TABLE | |||||

| Name | А, мм | В, мм | С, мм | Н min | H max |

| LT.110 | 80 | 110 | 150 | 60 | 145 |

| LT.120 | 90 | 120 | 160 | 60 | 155 |

| LT.130 | 100 | 130 | 170 | 60 | 170 |

| LT.140 | 110 | 140 | 180 | 60 | 190 |

| LT.150 | 120 | 150 | 190 | 60 | 210 |

| LT.160 | 130 | 160 | 200 | 65 | 230 |

| LT.170 | 140 | 170 | 210 | 65 | 255 |

| LT.180 | 150 | 180 | 220 | 65 | 275 |

| LT.190 | 160 | 190 | 230 | 65 | 295 |

| LT.200 | 170 | 200 | 240 | 70 | 320 |

| LT.210 | 180 | 210 | 250 | 70 | 340 |

| LT.220 | 190 | 220 | 260 | 70 | 360 |

| LT.230 | 200 | 230 | 270 | 70 | 380 |

| LT.240 | 210 | 240 | 280 | 70 | 405 |

| LT.250 | 220 | 250 | 290 | 75 | 425 |

| LT.260 | 230 | 260 | 300 | 75 | 450 |

| LT.270 | 240 | 270 | 310 | 75 | 470 |

| LT.280 | 250 | 280 | 320 | 80 | 500 |

| LT.290 | 260 | 290 | 330 | 80 | 520 |

| LT.300 | 270 | 300 | 340 | 80 | 540 |

| LT.310 | 280 | 310 | 350 | 80 | 560 |

| LT.320 | 290 | 320 | 360 | 80 | 585 |

| LT.330 | 300 | 330 | 370 | 85 | 600 |

| LT.340 | 310 | 340 | 380 | 85 | 625 |

| LT.350 | 320 | 350 | 390 | 85 | 650 |

| LT.360 | 330 | 360 | 400 | 85 | 670 |

| LT.370 | 340 | 370 | 410 | 90 | 690 |

| LT.380 | 350 | 380 | 420 | 90 | 710 |

| LT.390 | 360 | 390 | 430 | 90 | 735 |

| LT.400 | 370 | 400 | 440 | 90 | 755 |

| LT.410 | 380 | 410 | 450 | 100 | 775 |

| LT.420 | 390 | 420 | 460 | 100 | 800 |

| LT.430 | 400 | 430 | 470 | 100 | 820 |

| LT.440 | 410 | 440 | 480 | 100 | 840 |

| LT.450 | 420 | 450 | 490 | 100 | 860 |

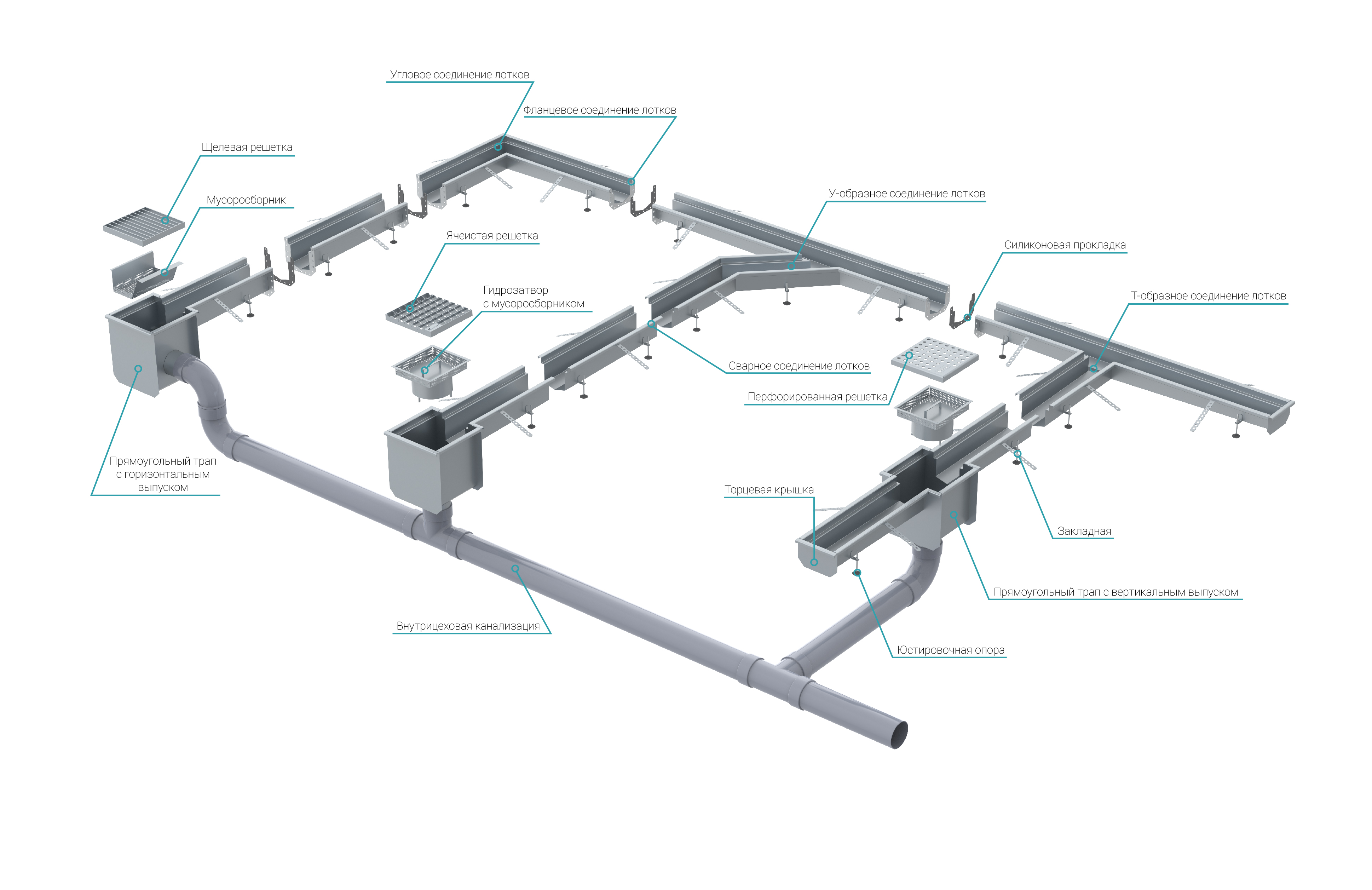

Stage 4

Model layout scheme

Stainless steel slots are widely used in different production plants, where waste water and manufacturing waste drainage are essential. Slots made of concrete and plastic might also be found but steel has more advantages, especially when you plan to buy rectangular drainage slots for food processing industry.

- Food grade stainless steel is resistant to moisture and corrosion.

- When cleaning the slots, it is safe to use cleaning chemicals and detergents without any risk of damaging the surface.

- Smooth slot surface doesn’t harbour microorganisms, which makes it easier to comply with sanitary and hygienic standards.

- Stainless steel is durable, tough and long-lasting material able to withstand any physical impact.

- It is chemically inert and no chemical emission occurs when in use.

- Stainless steel slot sections are joined together by welding, which results in a leakproof connection.

No other plastic or concrete slots have these properties. Concrete is usually affected by moisture even when additional agents are used, so its properties may deteriorate quite quickly. Plastic is affected by moisture as well, but it is less durable. Moreover, its surface might be damaged by different chemicals.

Thus, stainless steel slots present an ideal solution for sewerage systems sector-wide. Our Company provides a various range of slots, combining which you will surely get the system corresponding to the needs of your production.